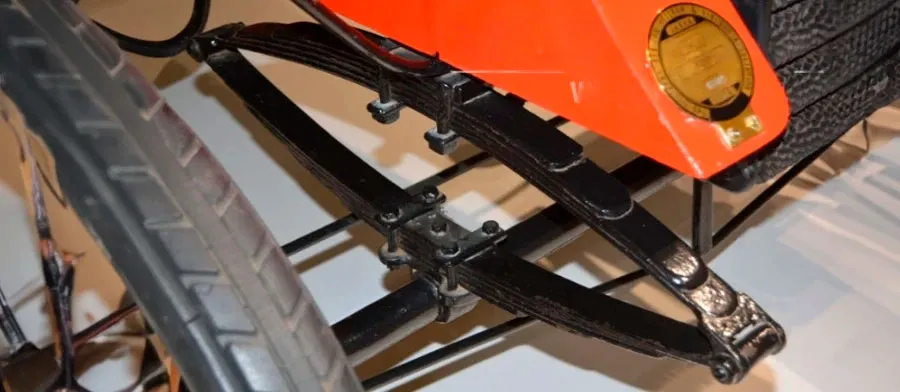

Springs have been used for a long time, long before cars were invented. They are made of steel and look like arcs, supporting the weight of the vehicle and holding the axle in place.

Automakers looking to improve the handling of light passenger cars have developed mono leaf springs. Because these springs are thickest in the center and thinnest at the ends, they create variable stiffness (like springs) and support the weight of the vehicle and hold the axle in place. As a result, the use of such springs improves the ride quality of small cars and provides a soft ride, helping to control the car around tight corners.

Currently, there are two most popular types of leaf springs: single leaf and multi-leaf. The former are used for small cars, and multi-leafs are used for larger vehicles. But what's the difference between them and what other types of springs are there?

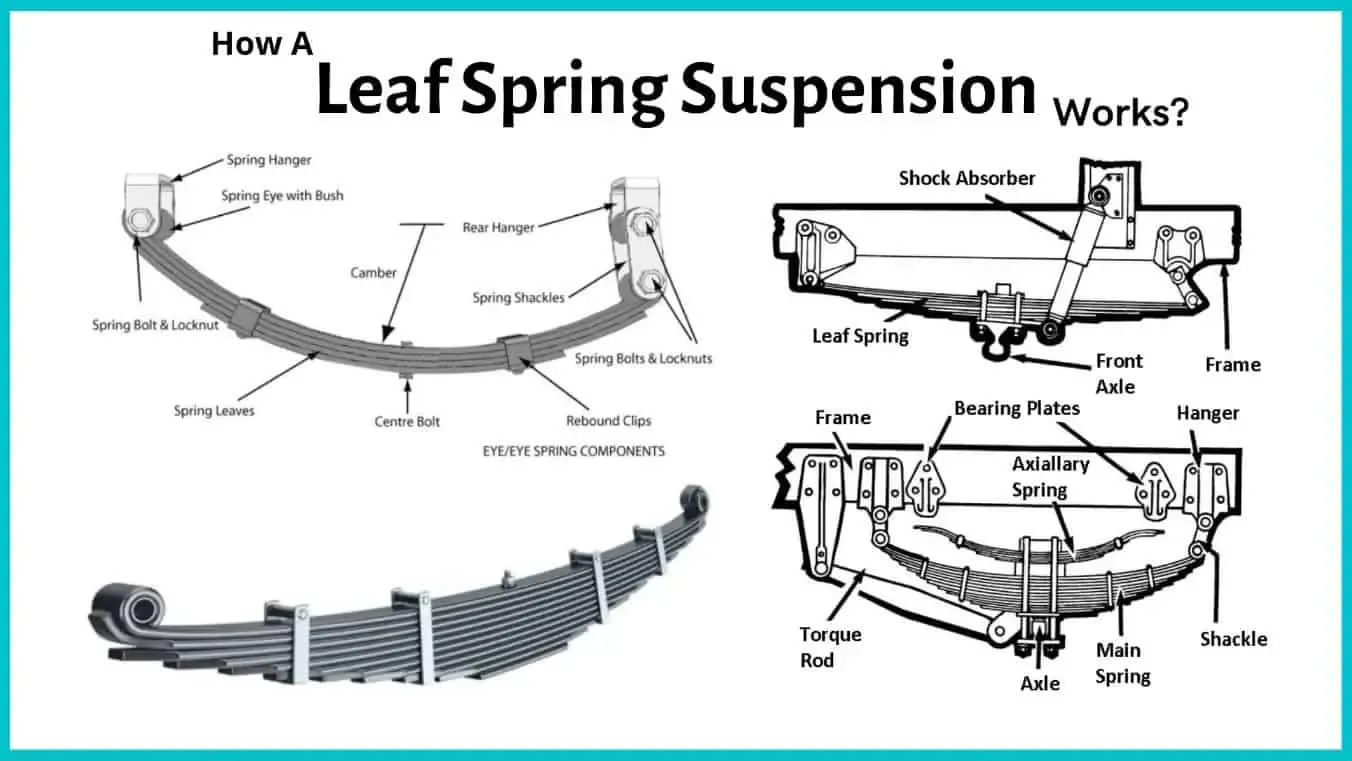

How does a leaf spring suspension work?

The central steel sheets are responsible for attaching the suspension to the car's axle, and the ends of the sheets are connected to the car frame using hinges or earrings.

Some suspension systems have only one metal sheet, not several, and such systems were used in the middle of the last century in the United States. These systems were installed on Ford cars, and only a few years later this system became popular among European automakers.

How the spring suspension works

When an obstacle is encountered, the leaf springs bend slightly, dampening all vibrations caused by the collision. If there are several sheets, the lower leaf spring is under a heavy load, so it is made shorter to achieve the least amount of bending. The upper leaf springs, on the other hand, are made longer to achieve greater flexibility and dampen the vibrations left behind by the lower leaves.

Today, leaf springs are used in pickup trucks, SUVs and large trucks. They are installed in the front, rear, along frame beams or transversely on different types of suspension.

Advantages of leaf springs in suspension:

- simple and have fewer moving parts that can wear out;

- hold the rear axle in place, so there is no need for complex suspension mechanisms;

- At high weight, they distribute the load more evenly over the car chassis compared to springs or torsion bars.

- The friction between several sheets as they slide helps dampen the natural effect of the spring's up-and-down bounce, making the ride more stable and reducing the load on the shock absorbers.

Disadvantages of leaf spring suspension:

- When leaf springs are mounted directly to the rear axle, the torque generated during hard acceleration or braking can cause the axle to spin. This results in vibration and significant squatting of the rear of the vehicle. This mounting also requires stiffer springs, which reduces the level of ride comfort that softer springs could provide.

- This design provides very little adjustability and is not suitable for suspension tuning, because adjustment is only possible by changing the number of sheets in the spring package or changing the material composition to change the strength and flexibility characteristics. For example, the Chevrolet Corvette T56 (5th generation) uses fiber-reinforced plastic springs.

What types of springs are there?

- Multi-leaf

- Mono leaf

- Semi-elliptical

- Quarter-elliptical

- Three-quarter elliptical

- Full elliptic

- Transverse

By the number of leaves:

- Multi-leaf spring

The most common type is the multi-leaf spring, which consists of more than one metal plate or sheet. These plates are stacked on top of each other, with the longest part on top. A center bolt is inserted through the thickest part to hold the plates together. Standard components have three to five flaps, but can also be found with more.

The multiple leaves increase the stiffness of the spring. The additional support leads to an increase in load capacity, so these springs are suitable for vehicles with a high payload. However, be careful when using leaf springs with too many leaves, as this can lead to excessive stiffness and cause an uncomfortable ride.

- Mono leaf spring

Another type is the mono leaf spring, made from a single sheet of metal. They have a thick center section and taper toward the edges to provide support, just like multi-leaf springs. They are mostly used in light vehicles.

By the shape of the leaf spring:

- Semi-elliptical leaf spring

This is the most common type of sheet listed here. It consists of several sheets of the same width and different lengths, including the top and longest sheet, called the "header sheet". They are attached to the car frame and the shackles. Semi-elliptic leaf springs are installed on the front and rear axles of many vehicles, mainly on the rear axle of passenger cars. They are affordable, serve for a long time, and do not require frequent repairs.

- Quarter-elliptic spring

This type is similar in design to a semi-elliptic leaf spring, but they are used mainly on older cars. A distinctive feature of this suspension component is that it is only half of a semi-elliptical leaf spring. One end is attached to the side of the frame with a bolt, and the other end is connected to the front axle. This type of spring is also called a cantilever spring.

- Three-quarter elliptical leaf spring

If you combine a semi-elliptical spring and a quarter-elliptical spring, you get a three-quarter elliptical spring. The quarter-elliptical part is located on top of the axle and is attached to the car frame. The semi-elliptic spring is connected to the frame through a shackle on one side, and the other end is attached to the quarter-elliptic spring.

The addition of an extra half of this suspension component provides additional support. The three-quarter elliptic leaf spring is popular on older cars.

- Full elliptic leaf spring

It is a combination of two semi-elliptical leaf springs that are connected opposite each other to create an oval shape. They are attached to the car frame and to the axle. Since both leaf springs deflect equally during compression, no leaf spring brackets are used.

Full-elliptic leaf springs are mainly used in older cars. Nowadays, they are rarely used because they do not ensure proper axle alignment.

- Transverse leaf spring

This type of leaf spring is very similar to the semi-elliptical leaf spring. The only difference is that it is inverted, so the longest leaf is at the bottom. It is attached from each wheel, not above them. The middle or thickest part is attached through a U-bolt. They are also mainly used in older cars, often in independent suspensions.

How to determine the wear of leaf springs?

When worn, the springs lose their elasticity and begin to sag. As a result, the height of the car decreases. If you suspect that the spring is worn out, it is recommended to measure the height yourself and compare it with the manufacturer's specifications. Reduced height and loss of spring rebound can lead to complications such as the car sinking on bumps, which is harmful to the suspension components and the entire vehicle.

In addition to the above, the springs can develop cracks and corrosion over time. When the rubber bushings in the leaf spring lugs and shackles dry out, the ride can become harsher. You can find the right mounting hardware for your springs at this link.

How do I maintain the springs?

When a driver has just bought and installed springs, the last thing he wants to think about is repair and maintenance. But it is better not to be lazy with the last point and not to ignore the need to periodically check the condition of the springs on the car.

These simple steps will help to significantly increase the life of the suspension:

- Keep an eye on the condition of the bushings mounted on the front spring mount. Their declared service life is 50,000 km, but it may vary depending on the terrain, driving style, and other factors;

- Periodically check the condition of the bolts and nuts. Vibration causes the strongest connections to gradually loosen and untwist. Before you leave, assess how tight the bolts are and tighten them for warranty. It is generally recommended to do this every 7,000 to 10,000 kilometers;

- In the rear lug, where the spring is in a floating position, it is important to change the grease regularly. Dust, dirt, water spoil it, so you need to periodically add new grease. To add grease, use a powerful crowbar or tire iron to bend the spring plate and grease the space that opens up. But be careful not to hurt yourself, especially your fingers.

- The following lubricants can be used: solidol, lithol, graphite grease, etc.

PL

PL

CZ

CZ